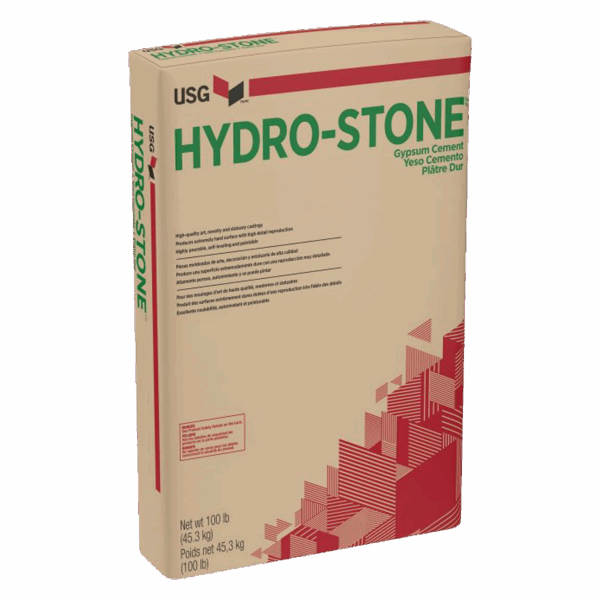

Hydro-Stone Gypsum Cement is especially suitable where high strength and resistance to water absorption are necessary. It is ideal for applications in both the tooling & prototyping and art & statuary categories. We supply the Hydrostone TB (Trophy Base) which is one of the hardest and strongest gypsum cements. Slightly higher setting expansion than Hydrocal, but is ideal in case moulds, press and stretch dies. The most widely used product for solid casts and statuary. Exceptionally strong gypsum cement designed for stretch-press dies and producing cope-and-drag equipment with high water absorption resistance. Produces high-quality, indoor novelty and statuary castings that require extremely hard surfaces and superior reproduction of fine detail.

Main Features

Hydro-Stone TB Gypsum Cement is especially suitable where high strength and resistance to water absorption are necessary. It is ideal for applications in both the tooling & prototyping and art & statuary categories.

Tooling & Prototyping

– Hydro-Stone Gypsum Cement is ideal for stretch-press dies where extreme surface hardness is required

– Offering greater expansion than Hydrocal gypsum cements

– Features a heavy, syrupy consistency, ideal for pouring into solid models or patterns (and making it ideal for filling multiple molds simultaneously)

– Adapts to most flexible moulding compounds, due to its high absorption resistance

– Sets in 17-20 minutes, after machine mixing

– Requires 32 parts water by weight per 100 parts plaster

Art & Statuary

– One of the hardest and strongest Hydrocal products, Hydro-Stone Gypsum Cement is used in the fabrication of high-quality art novelty and statuary castings

– Offering excellent paintability

– Can duplicate extremely fine details

– Works well in plaster and most flexible moulding compounds

– Is self-leveling, with low viscosity

– Provides fast set time for quick mold turns

NOTE – For best storage results, keep indoors in a dry, stable environment, away from drafts. Do not stack more than two pallets high.