Flexible Polyurethane Resin –

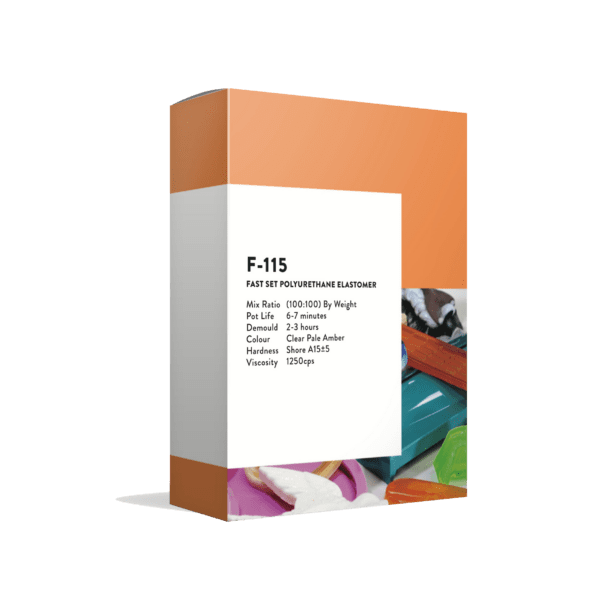

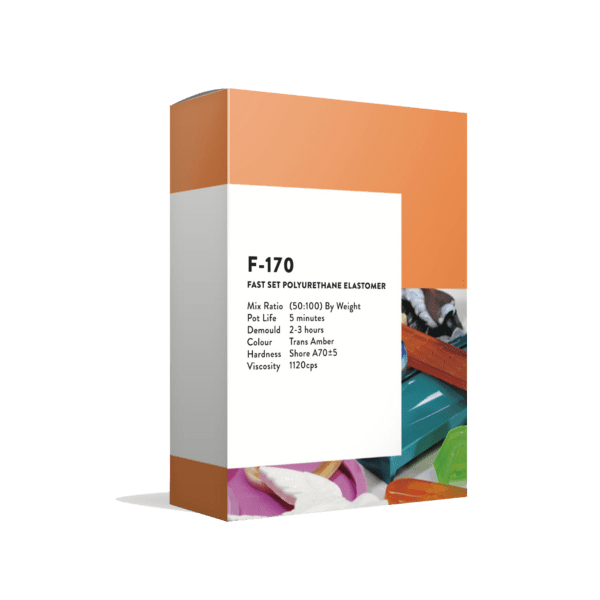

All our flexible polyurethane resin systems are production oriented with fast gel and fast de-mould times. Their work life provides you with sufficient time to vacuum de-gas and pour air-free parts. This means you can achieve near bubble free parts with maximum strength. They also have an easy mix ratio making them very easy to work with, and they have a low viscosity. As for colour, they are mostly translucent amber. As a result, you can easily pigment using the opaque range of PU pigments. We have a variety of types for different applications, including props, SFX, moulds, potting, mounts, and more. Another feature is the variety of Shore A hardness options. The F-Series starts at a 15A up to 90A Shore hardness. We also have a range of PT Flex polyurethane liquid rubber. These are perfect for model making and prototyping applications. They offer fast pour times (~5 minutes) and fast demold times (~2 hours).

Be sure to check the product descriptions to find out the differences between each one. If you need extra help with the vacuum degassing process, check out our anti-foaming agent AF-4. This handy product also assists in better resin flow and wet out in moulds. You can also have a look at our SC94 single component coating, polyurethane UV additive, and more. In addition to using the flexible polyurethane systems, consider the Poly Purge. The Poly Purge is sprayed into each bottle just before resealing to displace moist air and extend the product life.