No products in the cart.

Previous product

Back to products

JA12 Alloy Stick

$212.75 (inc. gst)

Next product

Langridge Dry Artist Pigment

From $27.60

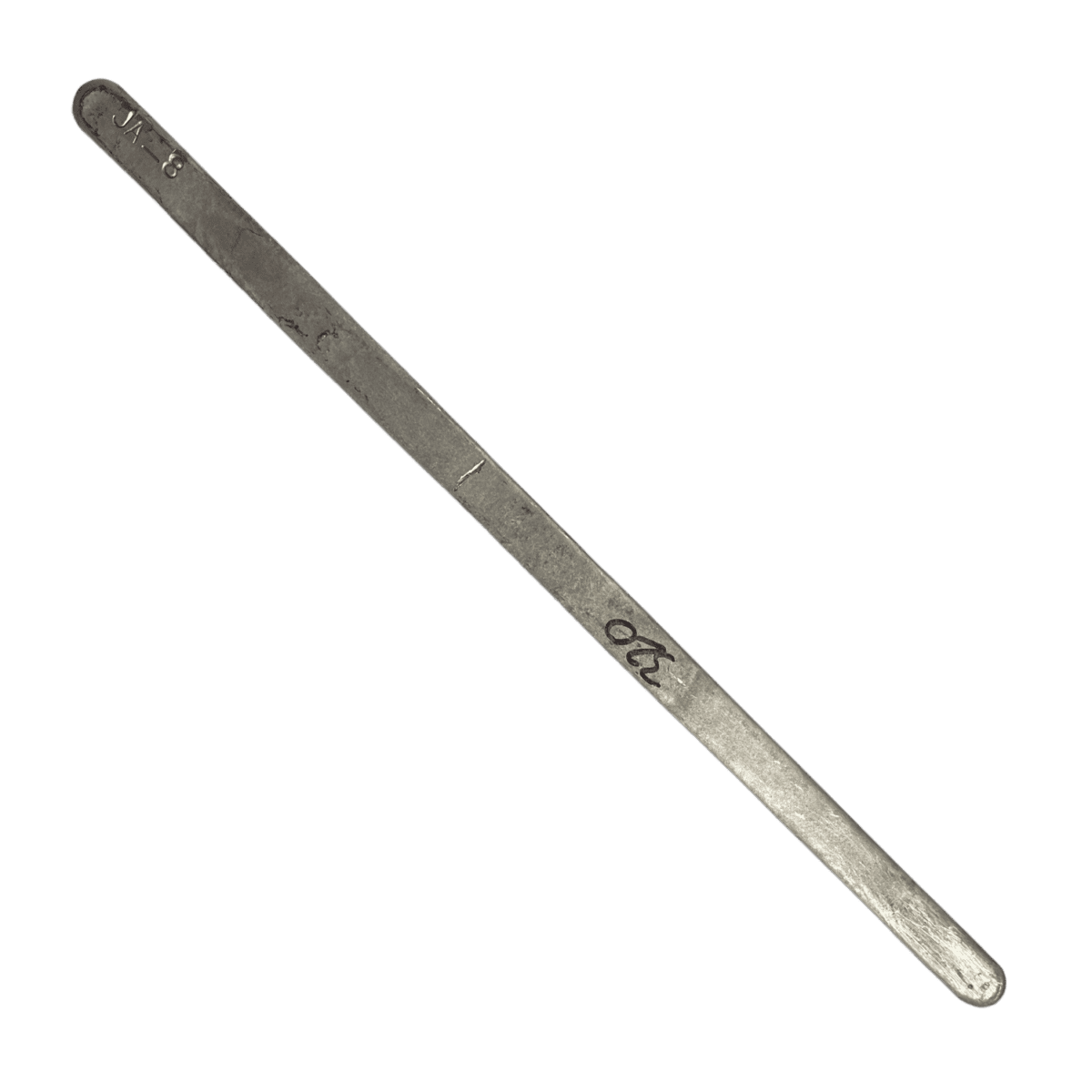

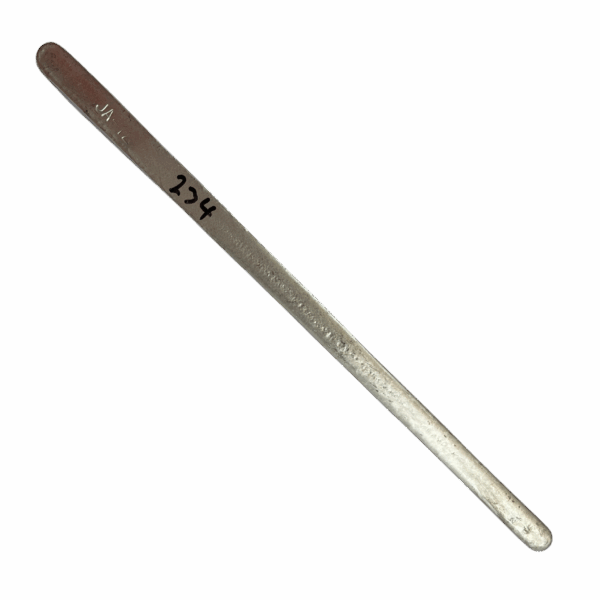

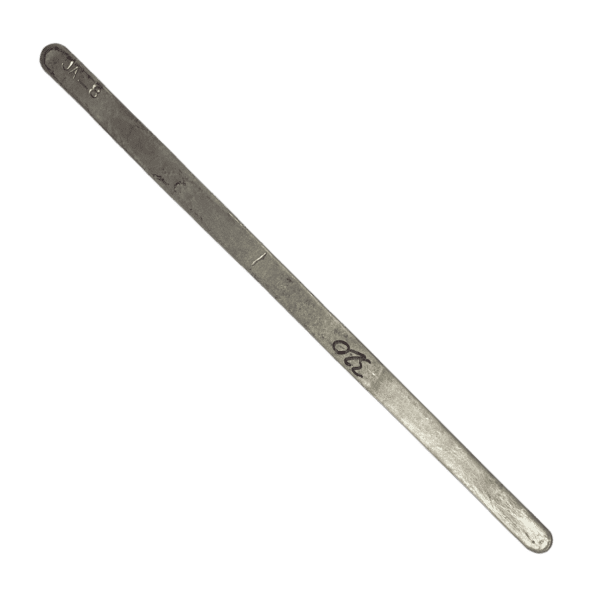

JA8 Alloy Stick

SKU: JA8

$92.00 (inc. gst)

*** Our website cannot supply custom weights, only per/kg – contact our Henderson store for a specific weight, as the average JA8 stick is between 250-400 grams***

Available at:

Auckland

SKU: JA8

Categories: Casting, Low Melt Alloys

Description

JA8 alloy offers superior ductility than some other low melt alloys, meaning that it can be partially bent without breaking.

The casting range is 270-320°C. The sticks average 300gm in weight. Approximate average content: Lead >45%, Tin 0-45% Antimony 0-10%, Cadmium 0-5%, Copper 0-1%.

It is now possible to cast quite intricate metal shapes, such as toy soldiers or model car parts using some of the newer silicones as a mould and low temperature white metal casting alloys. Previously this type of work was done using metal moulds, quite difficult to have made and quite expensive. Amongst the most popular of these silicones are M4670 and M4470. The M4670 is an addition cured silicone and has a firm Shore A rating of 55A, suitable for models with slight undercuts. The M4470 is a condensation cured silicone that has a 60A Shore hardness, making it a harder rubber with a tendency to be brittle, but having good resistance to heat and suitable for castings with few or no undercuts.

Please Note: While melting alloy metals is a simple process, it should never be attempted without suitable protective safety equipment such as goggles and heat proof gloves. It is not something that children should ever attempt without very adequate adult supervision.

Related products

JA12 Alloy Stick

$212.75 (inc. gst)

*** Our website cannot supply custom weights, only per/kg – contact our Henderson store for a specific weight, as the average JA12 stick is between 210-280 grams***

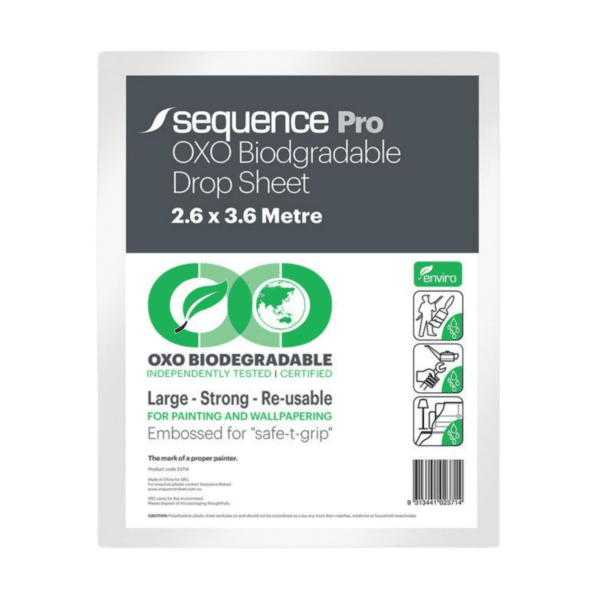

Plastic Drop Sheet

$5.75 (inc. gst)

A Biodegradeable plastic drop sheet to help protect your work space. This sheet has dimensions of 2.6m x 3.6m

Isopropyl Alcohol

From $19.55

Isopropyl Alcohol is probably the most essential product to have on hand at any time, especially in the make-up kit.

Surface Tissue

$7.48 (inc. gst)

Surface tissue is used in the inner corrosion barrier to form a resin-rich layer, and also in the exterior layer

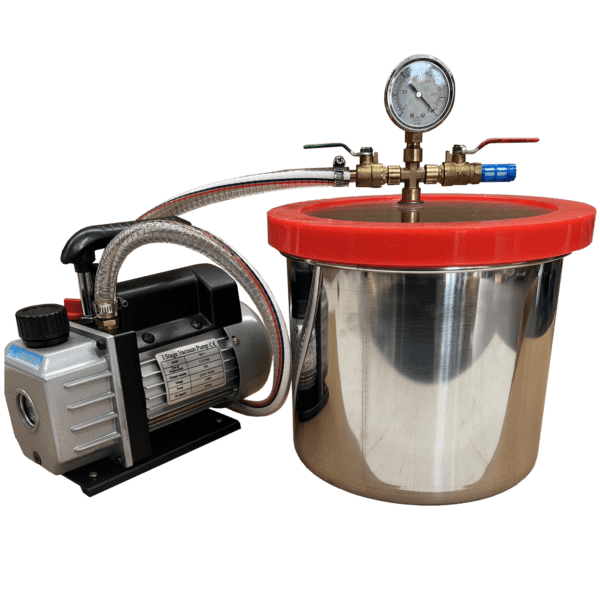

Barnes 6L Vacuum System

$632.50 (inc. gst)

This vacuum degassing unit is designed to remove air from resin and silicone systems prior to pouring. It is a

Eye Dropper

$1.73 – $6.90 (inc. gst)

Eyedroppers are ideal for adding liquid pigments to resins, or for creating effects in resin art using Isoproyl Alcohol or

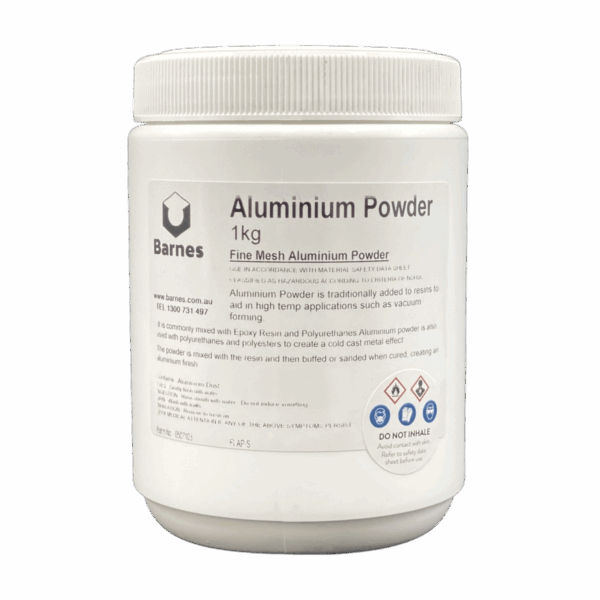

Aluminium Powder

From $35.65

Aluminium Powder is traditionally added to resins to aid in high temp applications such as vacuum forming. It is commonly

Sold out

Close

AF-7 Anti-Foaming Agent

$69.00 (inc. gst)

AF-7 Anti-Foaming Agent has been developed as an extremely effective, air release agent for Water Clear polyurethane material systems. Its